内容介绍

本期的绘本分享是英文绘本故事《I'm a Caterpillar》,翻译成中文名为:我是一条毛毛虫,小朋友们你们觉得蝴蝶漂亮吗?大家都有过被美丽蝴蝶惊艳,或者追逐着蝴蝶奔跑的经历吧~那你知道蝴蝶是怎么来的,是由什么变成的吗?让我们听听有关蝴蝶的故事吧!

I am a caterpillar.

我是一条毛毛虫。

Munch.Crunch.

吭哧,噶哧,使劲吃。

I'm getting bigger!

我越长越大!

Munch.Crunch.

吭哧,噶哧,使劲吃。

图片预览

下载地址

链接: https://pan.baidu.com/s/1culy7sofyDPZdziBUOy6cQ?pwd=mpc6 提取码: mpc6 复制这段内容后打开百度网盘手机App,操作更方便哦

xiaoyixinya

我热爱这样的想法, 去那么多国家。真棒。 拉森地貌 我一直梦想, 参观你们描述的目的地。感谢激励。

氛围绝佳。由衷感谢 心情。 後宮展區 阅读你的博客, 我看出, 旅游让人相连。无限感谢 积极能量。

阅读你的博客, 我感受到, 旅游让人相连。万分感谢 美好的心情。 歷史軍事 我经常计划, 看到你们相册那样的地方。谢谢启发。

出色的 旅游网站! 越来越棒! 根特當代藝術博物館 我非常尊敬, 真实的旅行者分享建议。你的项目 就是 关于这些的。干得好。

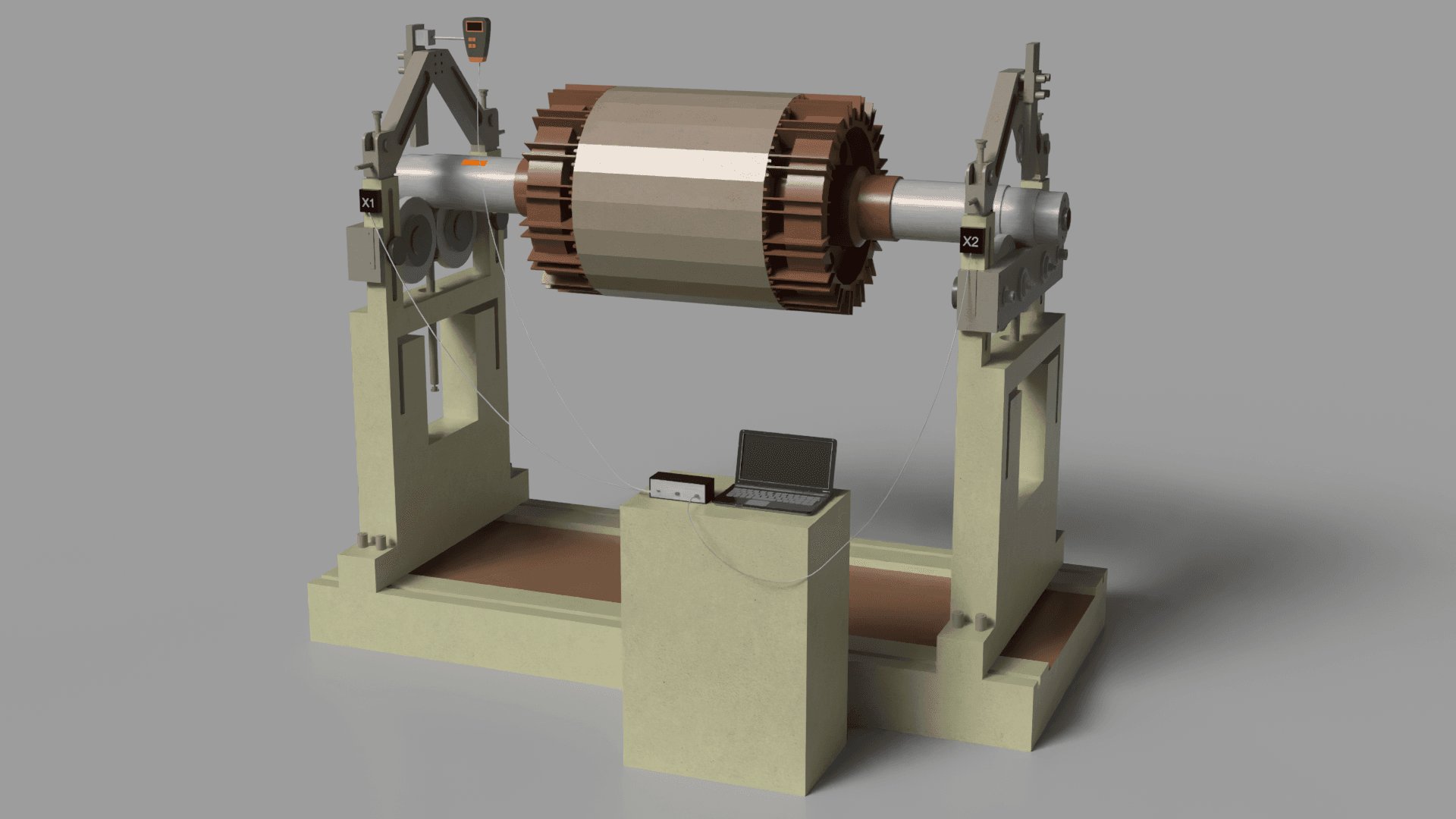

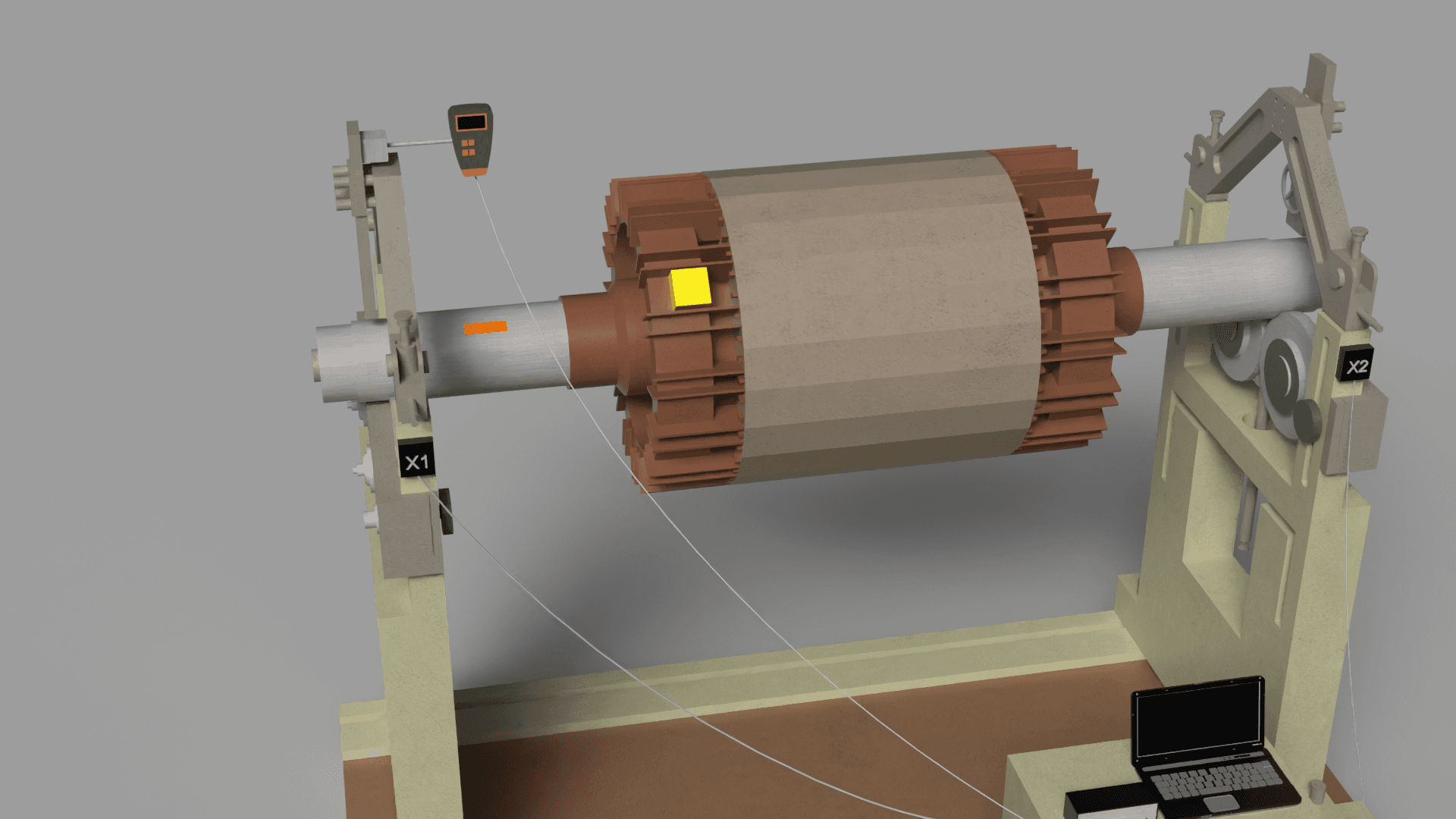

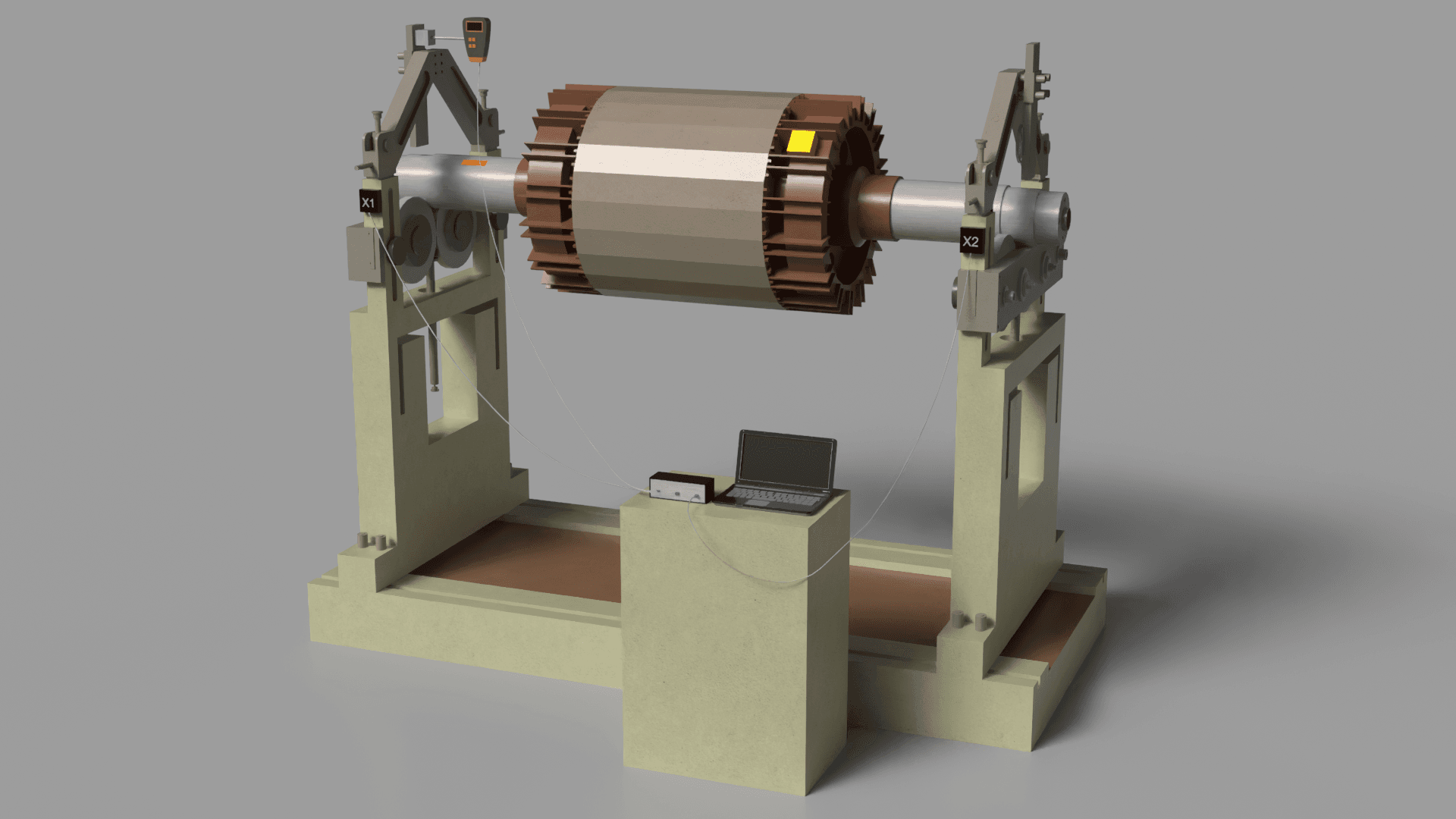

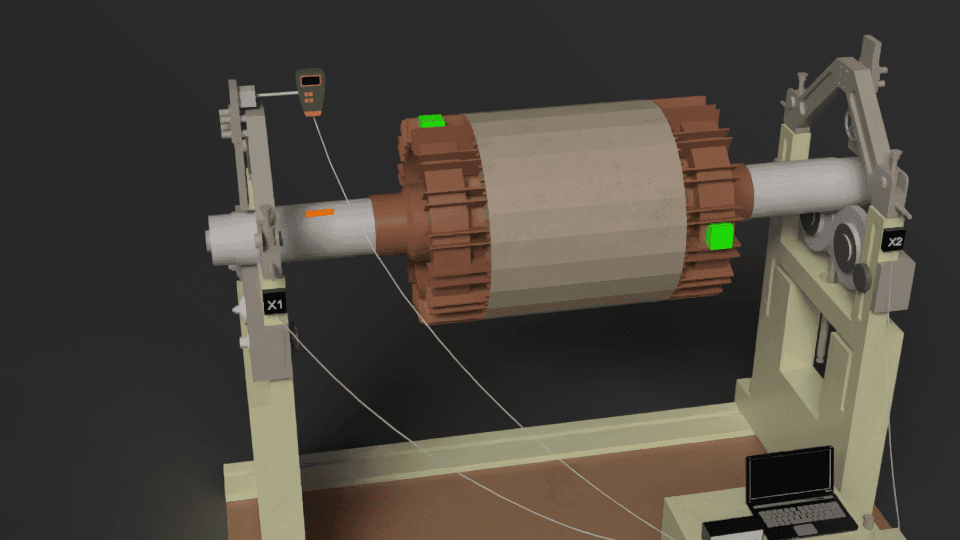

Bring the rotor to its normal operating rotational frequency. The application will acquire data on vibration magnitude, rotational velocity, and phase angle to determine the initial imbalance state. Mounting the Test Weight

Stop the rotor and attach a trial weight at a specific location on the rotor. The weight's mass can be specified within the software (e.g., in grams). Run the rotor again, allowing the software to measure the effects of the trial weight on vibration and phase.

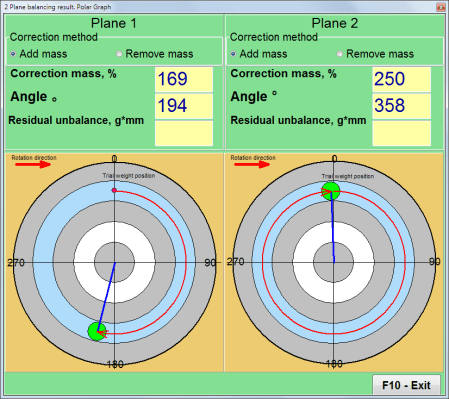

Computing the Compensating Weight Based on the measured data, the software automatically calculates the correction weight parameters: mass and installation angle. The calculated values are presented on-screen in both numerical and graphical formats.

Installing the Correction Weight Mount the calculated corrective weight onto the rotor at the specified location and angle. If necessary, perform intermediate checks to verify that the imbalance is being reduced.

Final Check and Balance Confirmation After installing the correction weight, run the rotor again and check the residual vibration level. If the measured vibration falls within the tolerance defined by ISO 1940, the balancing process is considered successful. Should the vibration still be excessive, repeat the balancing steps, making further adjustments to the corrective weight as needed. Creating a Balancing Report The balancing results are saved in the software's archive. You can create and print a report containing vibration data, correction weight mass, and its installation angle. Post-Balancing Checklist Double-check that all weights and sensors are securely fastened. Check that the rotor's rotation is smooth and free from undue noise or vibration. In cases where the rotor is integrated into a more complex system, ensure the correct operation and interaction of all related components.Following this procedure enables accurate balancing, minimizes vibration, and prolongs the service life of the equipment.

Instagram: https://www.instagram.com/vibromera_ou/

Youtube : https://youtu.be/guA6XJ-ArZM?si=vmkuX7RILzKBl0zL

Our website about <a href="https://vibromera.eu

"> Rotor balancing videos

Machinio: https://www.machinio.com/listings/98380186-portable-balancer-vibration-analyzer-balanset-1a-full-kit-in-portugal

Facebook: https://www.facebook.com/marketplace/item/350151228150722

gbyrvn20896IC-企业建站!收录请看过来!http://www.myinfinitebanking.com//